ALKA Epoxy Flooring SyStems

Epoxy Floor Coating Services by Accredited Contractors5 Years of Real Warranty | Australian-Made Quality Products

Sydney Epoxy Flooring Solutions for Warehouses, Workshops, Factories, Carparks, Food Processing, Pharma, Chemical Industries, Commercials & Residentials.

Discover Various Types of Epoxy Flooring System

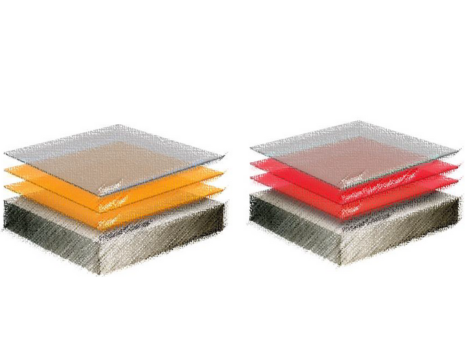

Conventional: Three Coats System.

– 100% Solid Epoxy

– Water-Based Epoxy System

UV resistant: Four Coats Poly Aspartic coating

Decorative metallic flooring

Abrasion Resistance: High Build Epoxy System

Self-level epoxy system

Food Grade Epoxy & Polyurethane coating system

Heavy Industrial High Impact Resistance

Chemical Resistance floor Coatings system

Sports Flooring & tartans

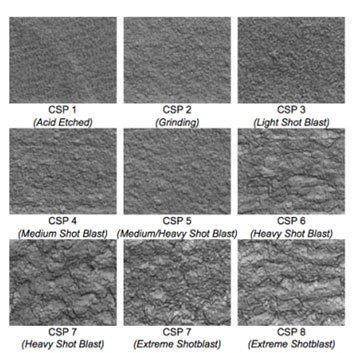

Surface Preparation

Resinous floor coating systems need a CPC 3 profile that could be achieved by diamond grinding.

In some severe cases, a harsher preparation may be required which can be achieved by shot blasting the floor. This has been shown in the image below.

Captive vacuuming assures a dust-free process and a safe hazard-free project.

All the major cracks and imperfections of the floor can be rectified in this step. To be able to achieve this, we use epoxy grout and apply it on the surface with a flat trowel or flat squeegee applicator. After the mortar is fully set, we grind it back to achieve a flat and smooth surface.

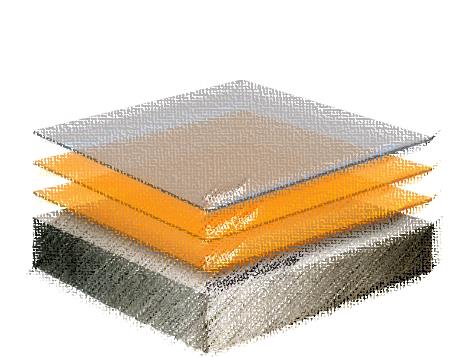

Three Coats Epoxy Coating System

This system is the most common method for warehouses and trafficable areas. This system has a good abrasion resistance, good chemical resistance and poor UV resistance.

1. Applying a penetrating Alka 104 epoxy primer system

2. Applying two coats of 100% solid ALKA 110 epoxy coating system

DFT: 350-500 microns approx.

Some typical areas of use: Warehouses | Storage Areas | Carparks

UV Resistance Four Coats

Polyaspartic Coating System

This system can be used in exterior industrial areas or interior areas with high exposure of sun. It has a very good abrasion resistance, good chemical resistance, and is extremely UV resistant.

1. Applying a penetrating Alka 104 epoxy primer system

2. Applying two coats of 100% solid Alka 110 epoxy coating system

3. Applying 100% solid ALKA 210 polyaspartic coating system.

DFT: 0.5 mm approx.

Some typical areas of use: Warehouses | Storage Areas | Carparks

Decorative Metallic Flooring

This system has vibrant metallic pigments instead of normal pigments and used in a high-end showrooms and malls. It has a very good abrasion resistance and is extremely UV resistant.

1. Preparation of the floor with epoxy mortar to produce a level floor,

2. light grinding and patching up all the imperfections,

3. Applying 100% solid ALKA 110 roll-on epoxy coating system,

4. Applying 100% solid ALKA 210 trowel-on polyaspartic system mixed with metallic pigments to the thickness of 1-2 mm.

DFT: 1-3 mm approx.

Some typical areas of use: Showrooms | Shopping Centres | High-End Garages

Abrasion Resistance / High traffic

This system has a much higher thickness comparing to normal three coats system as it contains a physically enhanced matrix of resin and bauxite grits. It has an extremely high abrasion resistance and good chemical resistance.

1. Applying ALKA 104 penetrating epoxy primer,

2. Applying 100% solid ALKA 110 roll-on epoxy coating system, then broadcasting bauxite grits to strengthen the floor

3. Applying two consecutive coats of 100% solid ALKA 110 roll-on Epoxy coating system.

4. (For exterior uses) An extra coat of 100% ALKA 210 polyaspartic roll-on coating system.

DFT: 1-3 mm approx.

Some typical areas of use: High Traffic Areas and Ramps | Bridges | Forklift Bays | Warehouses

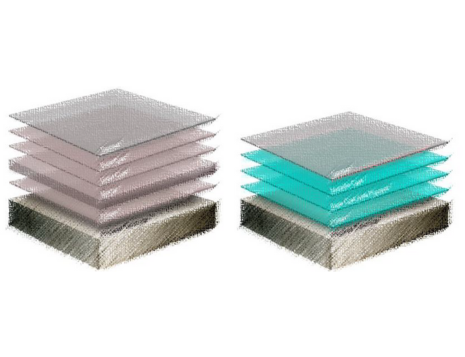

Self-Level Flooring

This system has a much higher thickness comparing to normal three coats system and it can create a perfectly smooth surface. It has a good abrasion resistance and good chemical resistance.

1. Applying Alka 104 penetrating epoxy primer,

2. Applying 100% solid Alka 110 epoxy flooring system,

3. Applying 100% solid Alka 110 roll-on Epoxy coating system.

4. (For exterior uses) one coat of 100% Alka 210 polyaspartic coating system.

DFT: 2-6 mm approx.

Some typical areas of use: Warehouses | storage areas | carparks | showrooms

Food Grade Flooring

This system has specially designed with hygiene floors in mind. Thus, it is impervious, hygiene and HACCP approved. It has a high abrasion resistance and high chemical resistance.

1. Applying 100% solid Alka 112T thixotropic epoxy coating system,

2. Applying 100% solid Alka 112 roll-on epoxy coating system, then broadcasting aluminium oxide grits to strengthen the floor,

3. Applying two consecutive coats of 100% solid Alka 112 roll-on Epoxy coating system.

DFT: 2-6 mm approx.

Some typical areas of use: Pharmaceuticals | Food Processing areas | Kitchens | Wash Bays

Heavy Industrial Flooring

High Impact Polyurea

This system has a complex and enhanced formulation that enables it to be extremely tough and at the same time extremely flexible with a flash curing time within the range of seconds, make it a perfect solution for super heavy industrial uses. It has an extremely high abrasion resistance, extremely high crack-bridging property, and extremely high impact resistance.

1. Applying a Alka Polyurea primer, tailored for each individual job,

2. Applying 100% solid Alka Polyurea coating with Graco™ two-component hot spray reactor,

3. (For exterior uses) An extra coat of 100% Alka 210 polyaspartic roll-on coating system.

DFT: 2-6 mm approx.

Certificate:

– AS/ NZS 4020:2018 Potable water approved

– HACCP approved

Some typical areas of use: Stadium seats | pharmaceutical floorings | truck beds | transportation vehicles | Heavy machinery

Chemical Resistance

Epoxy Coating System

This system has an extremely high chemical resistance against most chemicals such as mineral acids and can be formulated for each individual project. It has the capacity to be formulated as food grade floorings for breweries and vineries.

1. Applying Alka 113 epoxy primer,

2. Applying Alka 113 trowel-on epoxy coating system,

3. Applying Alka 113 roll-on epoxy coating system,

DFT: 1-3 mm approx. (tailored to individual job)

Novolac epoxies are a class of epoxy coatings that are specially made to resist aggressive high-concentration strong acids such as Hydrochloric acid 37% and Sulphuric Acid up to 75%. They can be used under extremely special circumstances.

Some typical areas of use: Breweries | Vineries | Chemical industries | Chemical Storages

Sports Flooring | Tartans

This system has been specially designed for sports filed. It is flexible, durable, tough and UV resistant.

▪ Applying Alka Tartan Premier,

▪ Applying a mixture of SBR Plastic Granule and Alka Binder to the thickness of 9 mm,

▪ Applying a mixture 100% solid Alka polyurethane thixotropic coating to fill up cavities and imperfections,

▪ Applying a 100% solid Alka Sport trowel-on self-levelling flexible Polyurethane to the thickness of 4 mm,

▪ Applying a wear and UV resistant Alka Aliphatic Polyurethane coloured coating,

▪ Applying Alka line marking system.

DFT: 13 mm approx.

Some typical areas of use: multipurpose playgrounds | walking | athletic tracks

Why to Choose Us?

We give manufacturer’s warranty and maintenance services on the floor coating systems applied by us as your exclusive contractor, with products formulated and manufactured in our factory here in Sydney, Australia.

DIY Epoxy Floor Painting Kits

Looking for Epoxy Flooring DIY Kits?

We refer you to our retail division, ALKA Coatings, as a first-rate supplier of quality epoxy in Australia.

We will give advice, support, and products you can rely on that not only provide superior protection but also help improve the efficiency of what they do.